PST-360 contactless position/angle sensor combines a through-shaft design with 360º absolute position feedback in an extremely thin package.

The angle sensor PST-360 is used for measuring angles between 30° and 360°.

Key features include through hole sensing where the shaft passes directly through the sensor, high accuracy absolute position feedback over 360°, and a true non-contacting sensing element. The new sensor incorporates a proprietary ring magnet with hall chip for the sensor element. This combination does not rely on gears or other rotating parts, maximizing robustness and sensing accuracy. The proprietary design provides a streamlined sensor with only one moving part along with electronics designed for harsh environments. Unlike optical encoders it has no sensitivity to dust or dirt and can tolerant high vibration cycles as the ring magnet never comes into contact with the sensing electronics. The result is a cost-effective product in an extremely small package.

Measuring just 9.8mm thick with a body diameter of 37mm and 50.0mm mounting hole spacing, engineers can now integrate a fully featured rotary sensor directly on their existing shafts without the packaging issues that typically accompany encoders or other through shaft sensing devices. The exceptionally low profile fits easily in places that were previously too narrow for pre-packaged rotary sensors. The standard models features 14mm or 17mm diameter double flatted shaft design. Custom rotor configurations are available from PIHER to adapt existing OEM shafts to the standard PST-360 Sensor.

MTS-360

Key Features

- Simple & robust magnetic design

- Endless rotation

- Programmable switch output

- Programmable linear transfer characteristics (some positive slopes & one negative slope can be programmed in the same transfer characteristic; 4 programmable points)

- Self-diagnostic features

- Over voltage protection and reverse voltage protection

- Virtually unlimited life. No maintenance needed over the product's life

- Designed to be fitted in harsh environment applications

- Slimline, low cost, long life

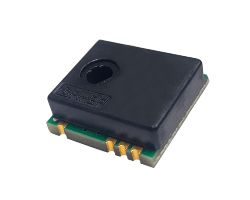

The MTS-360 provides a true breakthrough in contactless sensor technology by combining a through-shaft design with 360º absolute position feedback in an ultra miniature size. The result is the smallest fully featured rotary sensor on the market with reliability up to 50 million cycles.

With its tiny size of only 6mm x 17mm x 18mm (HxWxL), engineers can now integrate a fully featured rotary sensor directly on their PCB without the packaging issues that typically accompany encoders or other absolute position devices. The exceptionally low profile fits easily in places that were previously too small for pre-packaged rotary sensors.

The MTS-360 relies on patented Hall effect technology to enable for the first time true non-contacting through-hole shaft sensing using standard SMD features. The offset through-hole accommodates the vacuum pick up tool, allowing use in automated SMD assembly systems. The standard model features a 4mm double D-flat shaft and an (8) pad SMD footprint that is compatible in most reflow soldering systems.

The new device offers electrical angles up to 360° with no dead band and linearity as low as ±0.5%. Rated for use at -40ºC to +125ºC, the sensor can be programmed with full scale output with angles shorter than 360 degrees. Output is selectable between Analog, PWM up to 12 bits or Serial Protocol (SPI) up to 14 bits and includes a second output channel to provide a programmable switch signal. A redundant version with a dual core sensor in the same package is also available.

This ultra-miniature MTS-360 Rotary Position Sensor is ideal in optical imaging stabilization and precision biomedical devices, optical zoom devices, consumer electronics, instrumentation, HVAC systems, automotive control systems, marine controls, fork lift trucks, farm equipment, cranes, low speed motor feedback, valve position sensors and robotic and automation feedback system.